double cardan joint angle

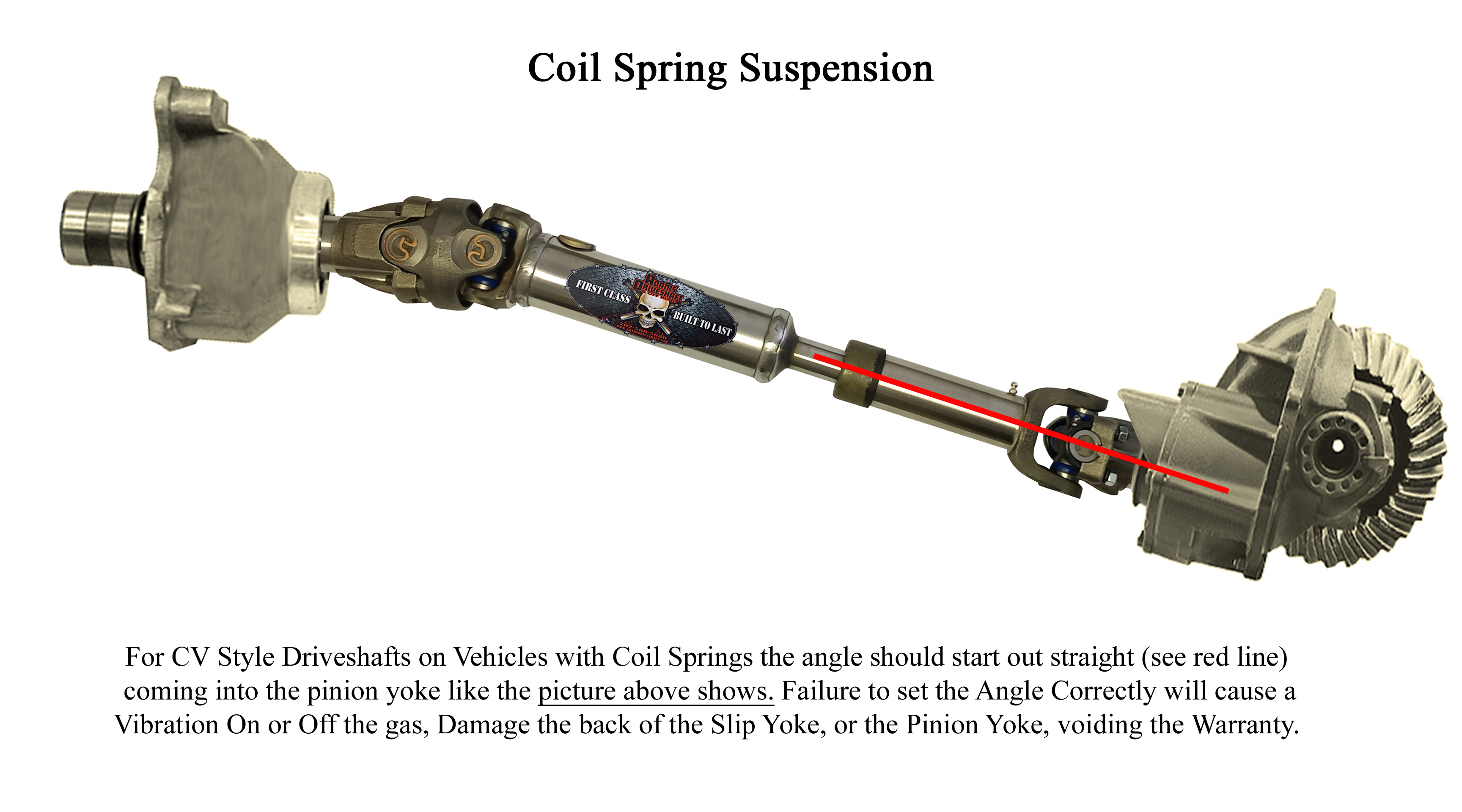

When you load the Jeep up it will move toward perfect and when you really load up heavy it can move a little higher than perfect. Any guidance would be wonderful from those who have this single cab double cardan joint setup and a lift as well.

GEWES has produced double cardan shafts for powered steered axles in the medium and heavy application range for more than 50 years.

. A stock Spicer double cardan CV joint can run successfully at about 22 and a High Angle Driveline double-cardan CV joint can be run successfully at as much as 32. Double Cardan joints allow to adjust angle A between input and output shafts even during rotary transmission. Where your driveline seldom sees a constant load U joint life becomes a difficult number to crunch.

A typical single cardan driveshaft should not exceed 12 degrees. 12 13 This centering device requires additional torque to accelerate the internals of the joint and does generate some additional vibration at higher speeds. This experience has led to the development of proven designs characterised by.

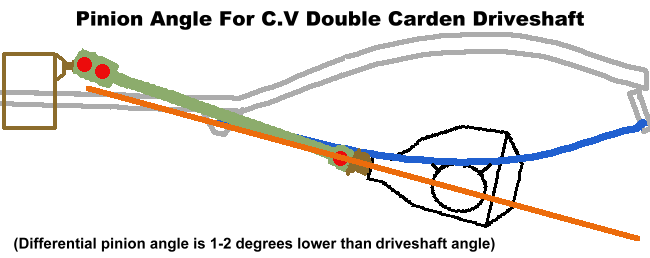

Agriculture Construction Defense Other Off- and On-Highway markets Centered Double Cardan Broschure English Centered Double Cardan Broschure German. This is why you should start out with an angle that is a little lower than perfect. The Ford Bronco II pinion is set around 17 degrees and has used a double cardan and constant velocity driveshaft.

AJ L is length of input shaft of the double cardan joint JK R y distance from centre of rotation of yoke to centre of first cross IK R y distance from centre of rotation of yoke to centre of second cross JI L im length of intermediate shaft of the universal joint it changes with the angle of rotation of the yoke θ. This case shows - 90 deg. If I zero to my frame for a reference point since I dont have a level surface at all my relative transfer flange angle is about 35 degrees and driveshaft about.

Suitable for constantly large operating joint angles Up to 50 max. Double Cardan joints require a centring element that will maintain equal angles between the driven and driving shafts for true constant velocity rotation. In the second method the axes of the input and output shafts are offset by a.

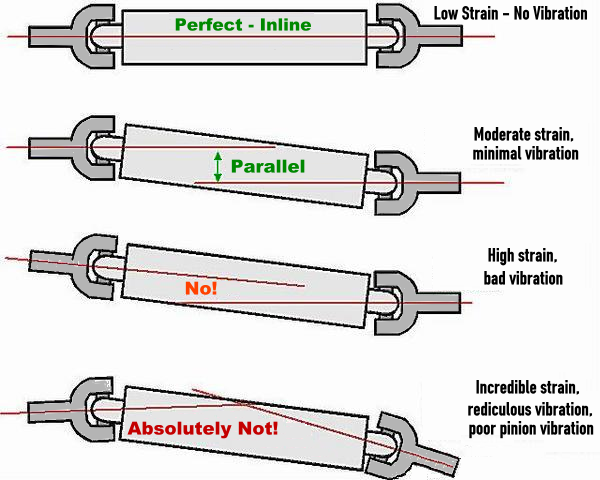

14 Thompson joint edit. If you double the angle you halve the life halve the load double the life and viceversa. While all within an acceptable range.

For reference on what were getting with the 9 combo on a 1350 here are a few pics to show the angles were seeing with NO GRINDING on the yokes but also using a Tom Woods. May not seem like much its roughly equal to driving 8 hours a day 5 days a week for 2 12 years. I got a front propshaft from a toyota hilux and replaced the TJ Wranglers rear shaft just had to have the lenght modified.

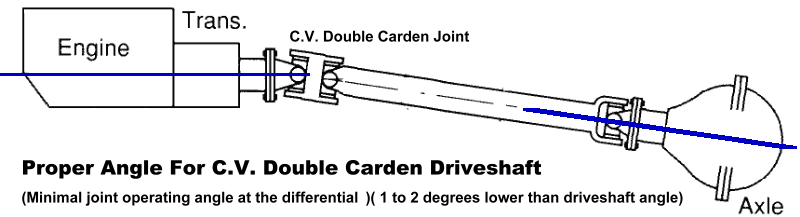

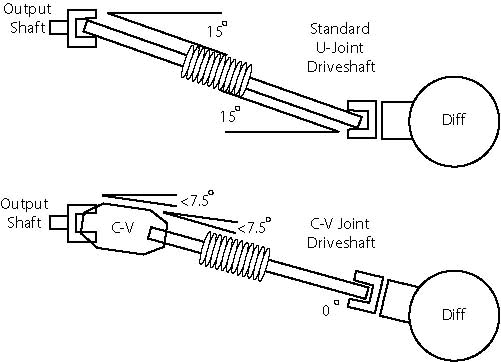

If the offset angles at both Cardan joints are equal the double-Cardan-joint driveline functions as a constant-velocity coupling when the magnitude of the relative phase angle is zero. This example shows two methods to create a constant rotational velocity output using universal joints. Guys around here beat the angle thing to death with graphics and protractors and laser.

Double Cardan joints for extreme drive shaft angles. Double cardan driveshaft top single cardan driveshaft bottom. This allows for successful driveshaft installations in vehicles with much more suspension height than a simple single-cardan shaft can accommodate.

In the first method the angle of the universal joints is exactly opposite. Paid R800 for the shaft at local scrapyard but just make cardican joint is in good working order. The output shaft axis is parallel to the input shaft axis but offset by some distance.

Large deflection angles up to 52 degrees and compact designs due to journal crosses with axle offset. Even if you matched the angles on a single. Though we were seeing 40ish degrees at the diff I seem to remember that around 35 degrees was max at the t-case using a single joint and MUCH less if you used a double cardan.

Provided that the angle between the input shaft and centre yoke is equal to the angle between the centre yoke and the output shaft the second Cardan joint will cancel the velocity errors introduced by the first Cardan joint and the aligned double Cardan joint will act as a CV joint. Right now my rear pinion is neither parallel with the transfer flange nor in line with the driveshaft. Angle Up to 6200rpm Maintenance free Smooth running due to advanced design Optimized robust centering SystemApplication.

Cdc Centered Double Cardan Driveshafts Walterscheid Powertrain Group

Proper Drive Shaft Phase Double Cardan Tacoma World

Billavista Com Driveshaft Bible Tech Article By Billavista

How Crucial Is Pinion Angle Sye Jeep Cherokee Forum

Measuring Your Early Bronco 1966 1977 Drive Shafts Tom Wood S Custom Drive Shafts

Billavista Com Driveshaft Bible Tech Article By Billavista

Billavista Com Driveshaft Bible Tech Article By Billavista

Billavista Com Driveshaft Bible Tech Article By Billavista

Double Cardan Joint Operating Angle Jeep Wrangler Tj Forum

Correct Driveshaft Angles For A 4 Lift Wj Jeep Enthusiast Forums

Driveline Geometry 101 Tom Wood S Custom Drive Shafts

Driveline Geometry 101 Tom Wood S Custom Drive Shafts

Cdc Centered Double Cardan Driveshafts Walterscheid Powertrain Group

How Does A Centering Yoke Work In A Double Cardan To Keep The Angles Equal Quora